Thank you for Joining Us at

SelectBIO Rotterdam

We thank you for attending our presentation and if would like to speak to us then we suggest you click the link below and schedule a call with our 3D printing expert to see how our technology & expertise can work for you.

H-Series

XY Resolution – 30µm to 53µm

Native 2K Projector

Open Source System

385nm/405nm Wavelengths

P4K UHD Series

XY Resolution – 30µm to 65µm

Native UHD 4K Projector

Open Source System

385nm/405nm Wavelengths

Pr110 4K Series

XY Resolution – 40µm to 55µm

Native 4K Projector

Open Source System

385nm Wavelength for Bio-compatible Parts

Request a Quote

Just fill in the form below and we’ll get back to you.

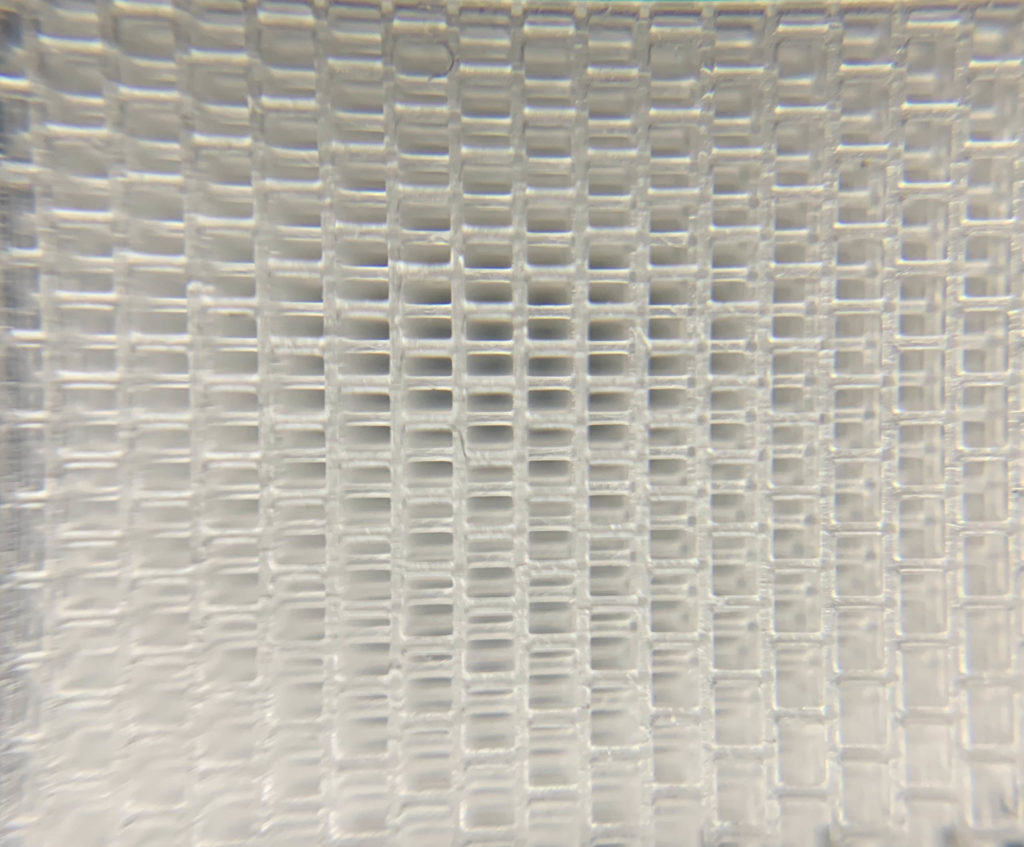

PDMS Master Mold

Faster Iterations – Create mastermolds using our formulated resin, Mastermolds for PDMS devices. Print, cast, evaluate and iterate in the matter of hours instead of weeks. Features as fine as 50µm.

Ease of use – Print, clean and cure your Mastermold and it is ready to use. Create your PDMS device in a conventional lab oven without losing any printed feature(s) or deterioration of the master. Cast PDMS can be bonded and sealed to a glass slide using oxygen plasma.

Lab-on-a chip

Dynamic Prototyping – Microfluidic materials formulated to allow researchers to create a wide range of designs, layouts and features.

Evaluate & Iterate Faster – A system built to go from concept to iteration faster and allows researchers to better evaluate their design for functionality.

Easy Post-Processing – A technology engineered to print microfluidic devices that are easy to post process and ready to use in a wide range of applications.

Bioscaffolds

Using the Cadworks3D 3D printer’s open source feature, users can use any 3rd party bio material to 3D print bio-scaffolds.

Biosensors Housing

Watch how 3D printing has changed the workflow of PhD candidate Surath Gomis at the Kelley Lab, University of Toronto.

Request a Sample Pack

Blog

3D printing paves the way for epifluidic devices with a skin-interfaced microfluidic device for sweat capture

The Tyler Ray team at the University of Hawai’i at Manoa harnesses the CADworks3D Pr110-385 printer and Clear Microfluidic Resin to establish a unqiue class of epidermal microfluidic device, called a ‘sweatainer.’ This device represents a groundbreaking advancement in the collection and analysis of sweat samples. 3D printing paves the way for epifluidic devices with

Design Guide to Clear Encapsulated Devices

Design Guide to Clear Encapsulated Microfluidic Devices < 5 minute read The fabrication of a complete, well-functioning microfluidic device requires a combination of basic 3D printing knowledge, careful planning, and iterative design testing. In this design guide for clear encapsulated microfluidic devices, we explore useful tips and techniques to equip users with the right tools

CADworks3D’s Master Mold for PDMS Device Resin empowers a sustainable and low-cost method for mass-producing LoaD device

Leveraging the CADworks3D PR110 printer and the Master Mold for PDMS Resin, a team of researchers at Sungkyunkwan University in South Korea paved the way for a scalable and green manufacturing process for polydimethylsiloxane (PDMS)-based microfluidic devices. CADworks3D’s Master Mold for PDMS Device Resin empowers a sustainable and low-cost method of mass producing Lab-on-a-Disc Devices