No Cleanroom. No Outsourcing. No Delays.

Create Functional Microfluidic Devices in 1 Day

With our complete 3D printing system, design, iterate, and produce fully functional microfluidic devices in just one day at benchside. High-precision 3D printers, specialized microfluidic materials, and a validated easy workflow give you full control, faster experimentation, and the freedom to innovate on your schedule.

Benchside Fabrication

A Complete 3D Printing System

Advanced 3D Printers Made for Microfluidics

Our 3D printers are designed specifically for applications in microfluidics and biotechnology, delivering high precision, fine feature resolution, and exceptionally smooth surface finishes.

Specialized 3D Materials

Even a great printer shows limited results with an incompatible material. Our materials are optimized for our printers and built for real lab applications, from molds for PDMS to clear monolithic structures.

Validated Processes

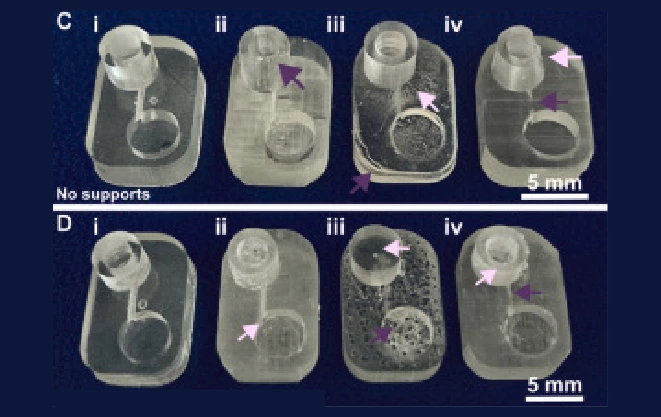

User methods are critical to the success of a print. So on top of training, we provide insights and tools for CAD file preparation, print parameter tuning, post-processing and maintenance guides.

NO CAD Experience? We Have a Solution.

Benchside Fabrication

A Complete 3D Printing System

Advanced 3D Printers Made for Microfluidics

Our 3D printers are designed specifically for applications in microfluidics and biotechnology, delivering high precision, fine feature resolution, and exceptionally smooth surface finishes.

Specialized 3D Materials

Even a great printer shows limited results with an incompatible material. Our materials are optimized for our printers and built for real lab applications, from molds for PDMS to clear monolithic structures.

Validated Processes

User methods are critical to the success of a print. So on top of training, we provide insights and tools for CAD file preparation, print parameter tuning, post-processing and maintenance guides.

WHAT THE SYSTEM CAN ACHIEVE

Biocompatible

Microfluidic Devices*

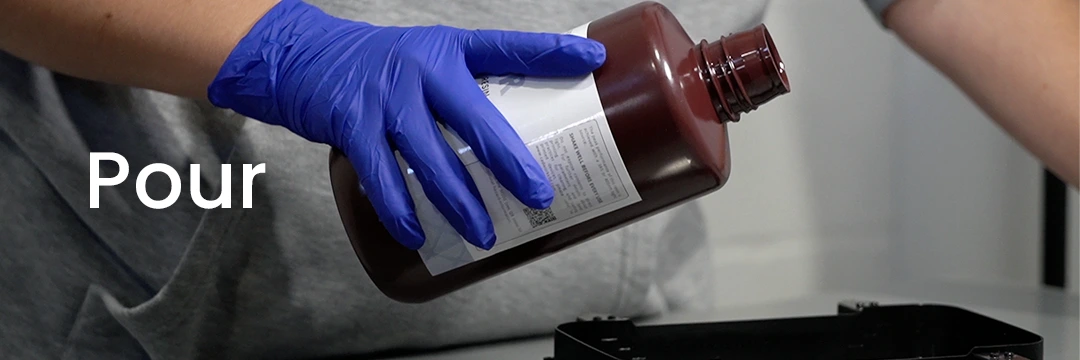

Benchside Workflow Built for Microfluidics

Simply design your chip, load the specialized 3D Materials, and start the print. After a quick rinse with IPA and a curing step, your device is ready for your research.

This workflow eliminates the need for cleanrooms, outsourcing, or polishing, allowing researchers to iterate rapidly and accelerate their experiments.

NO CAD Experience? We Have a Solution.

Bench-Ready ApplicationsPrinted with our Materials

BROWSE BY APPLICATION CATEGORY

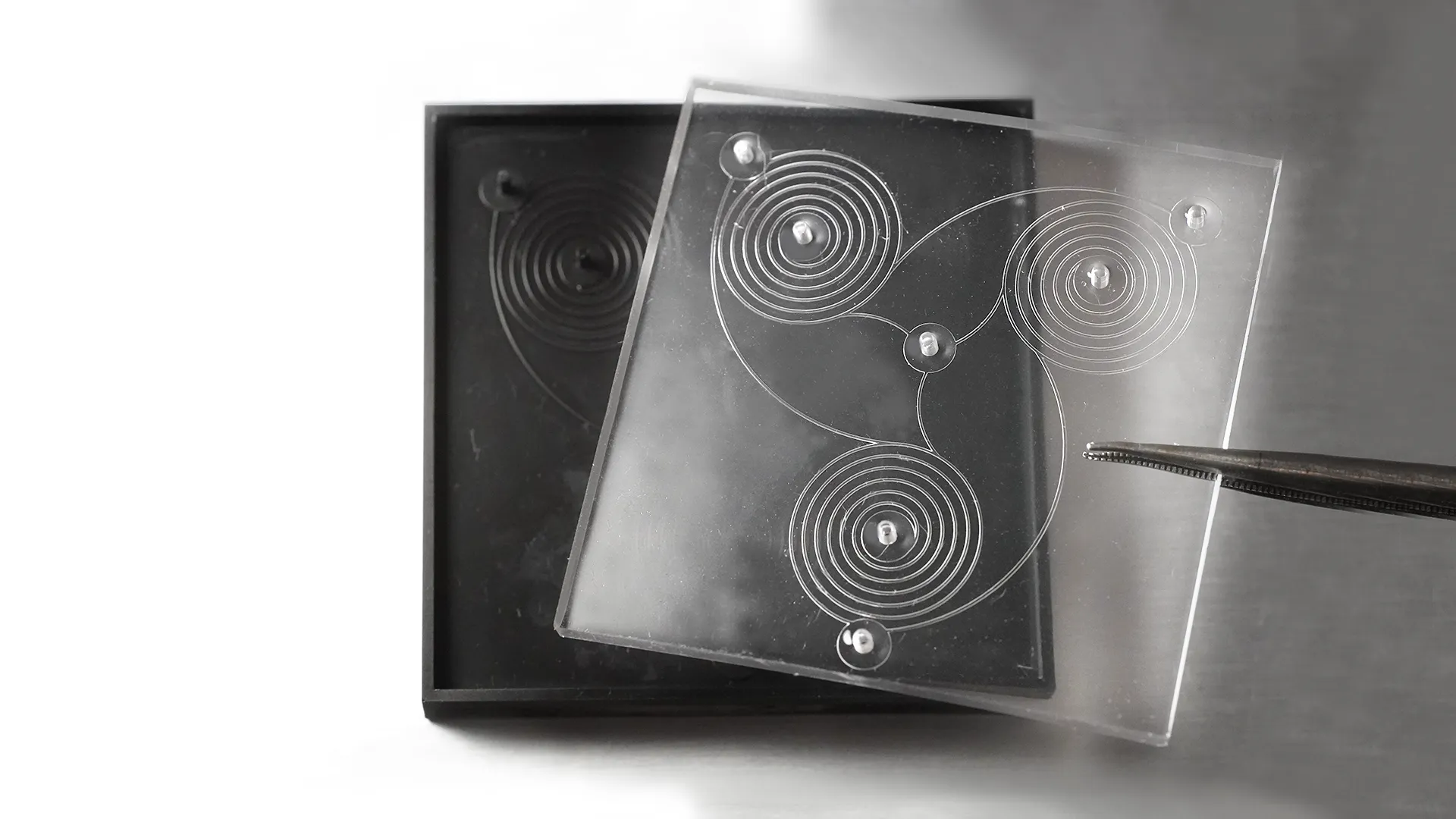

Applications shown 3D print with the

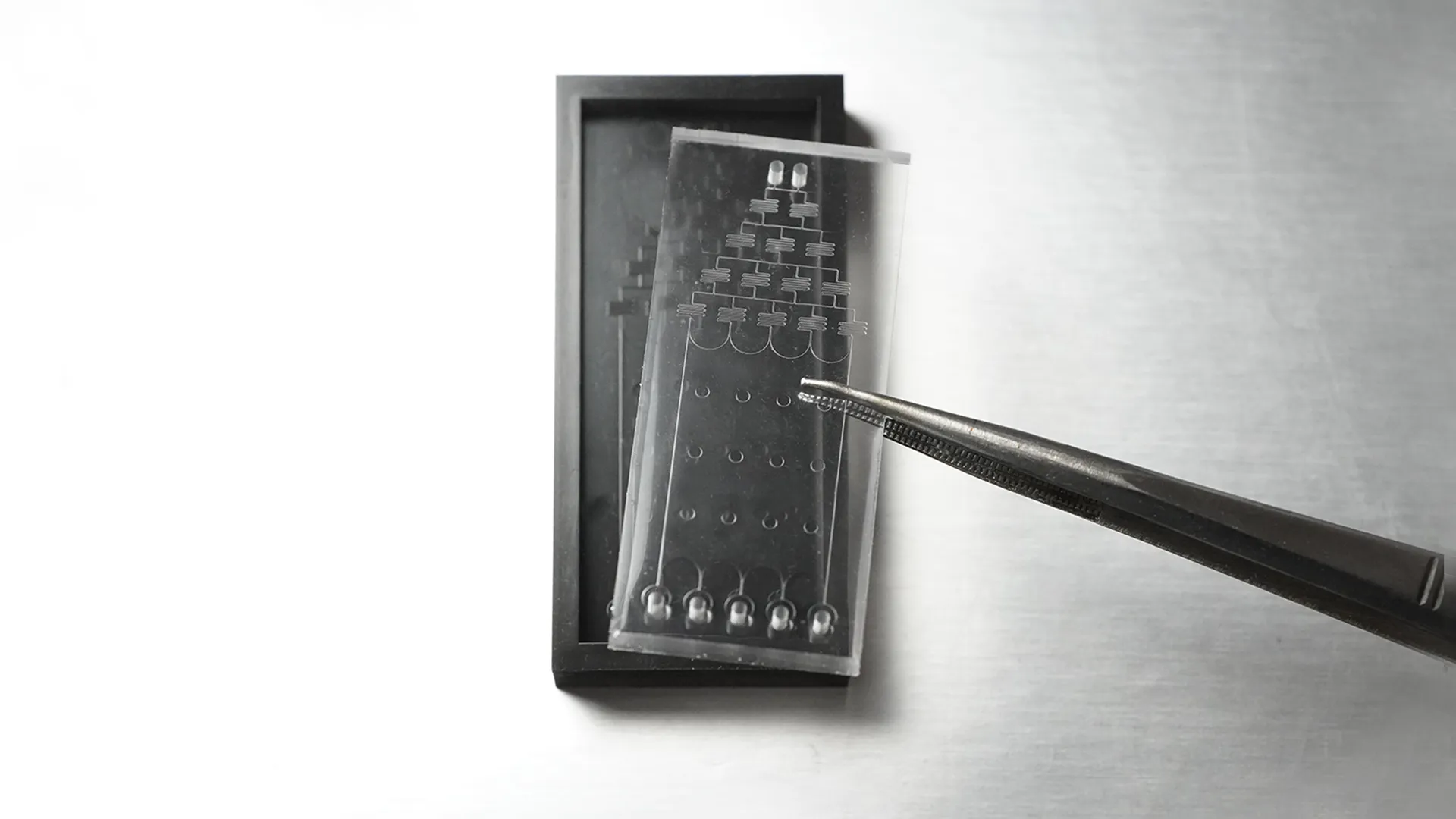

Master Mold for PDMS Photopolymer Resin – Rapid HD >

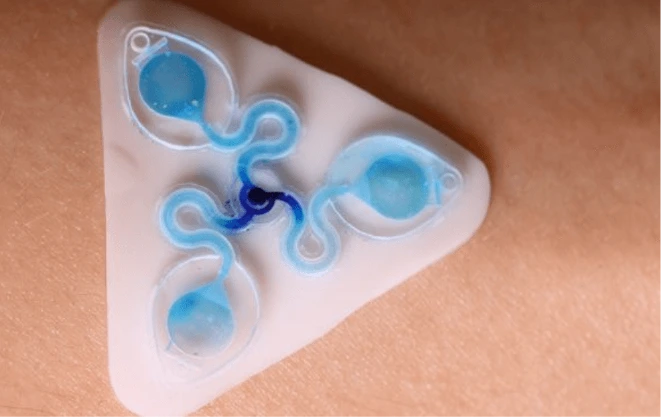

Spiral Microfluidic Device

Droplet Generator

Gradient Generator

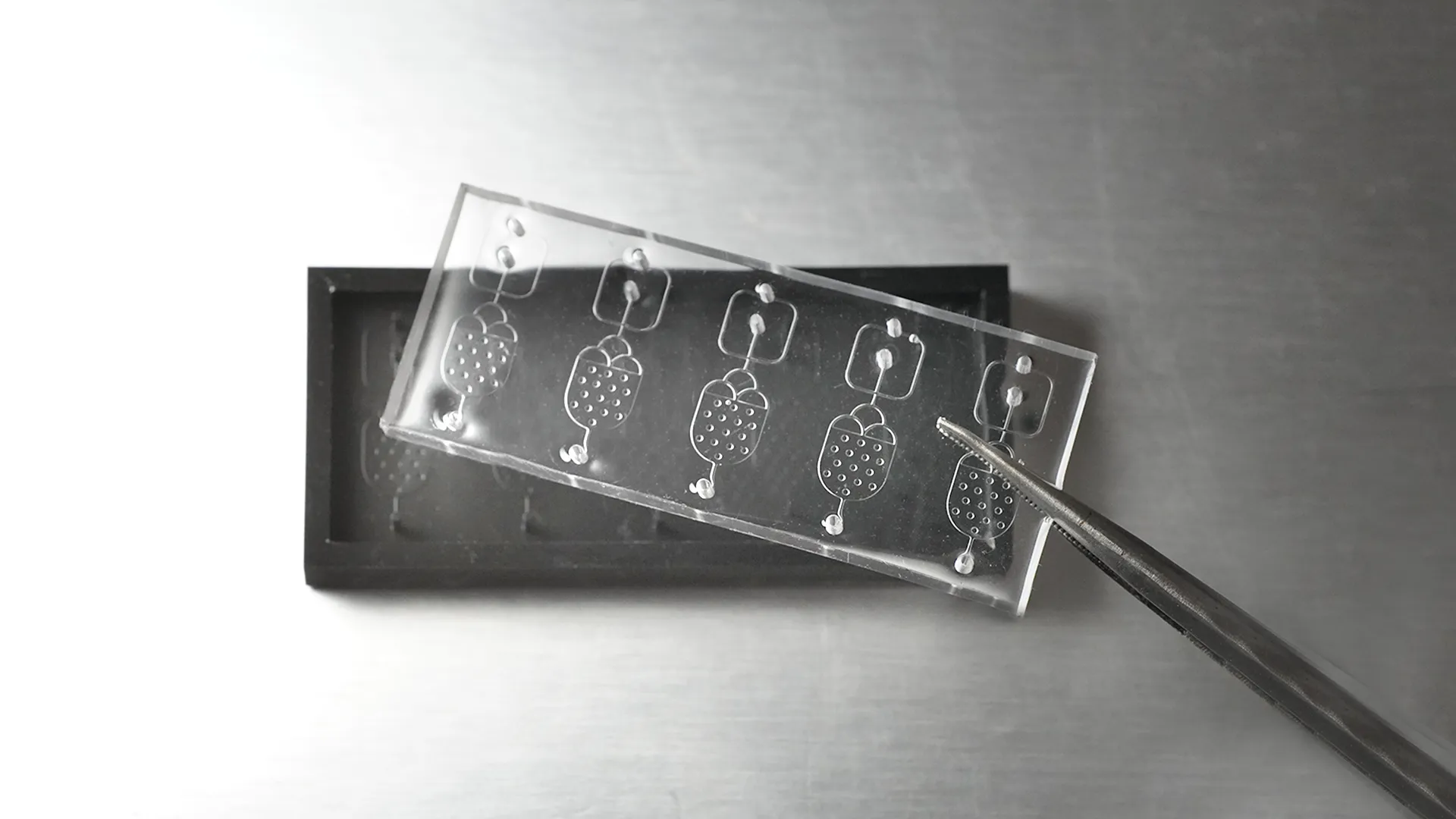

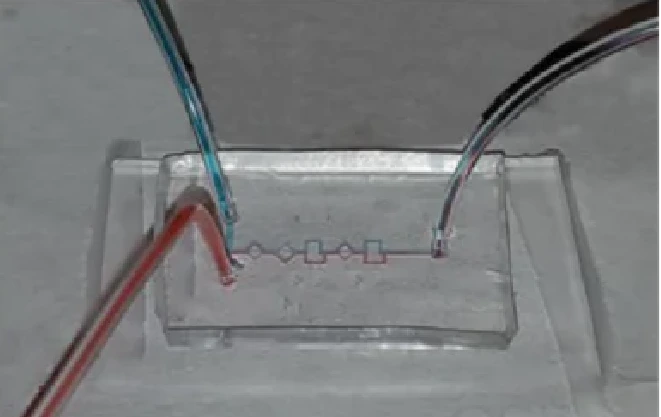

Applications shown 3D print with the Cyto-Clear Microfluidic Resin >

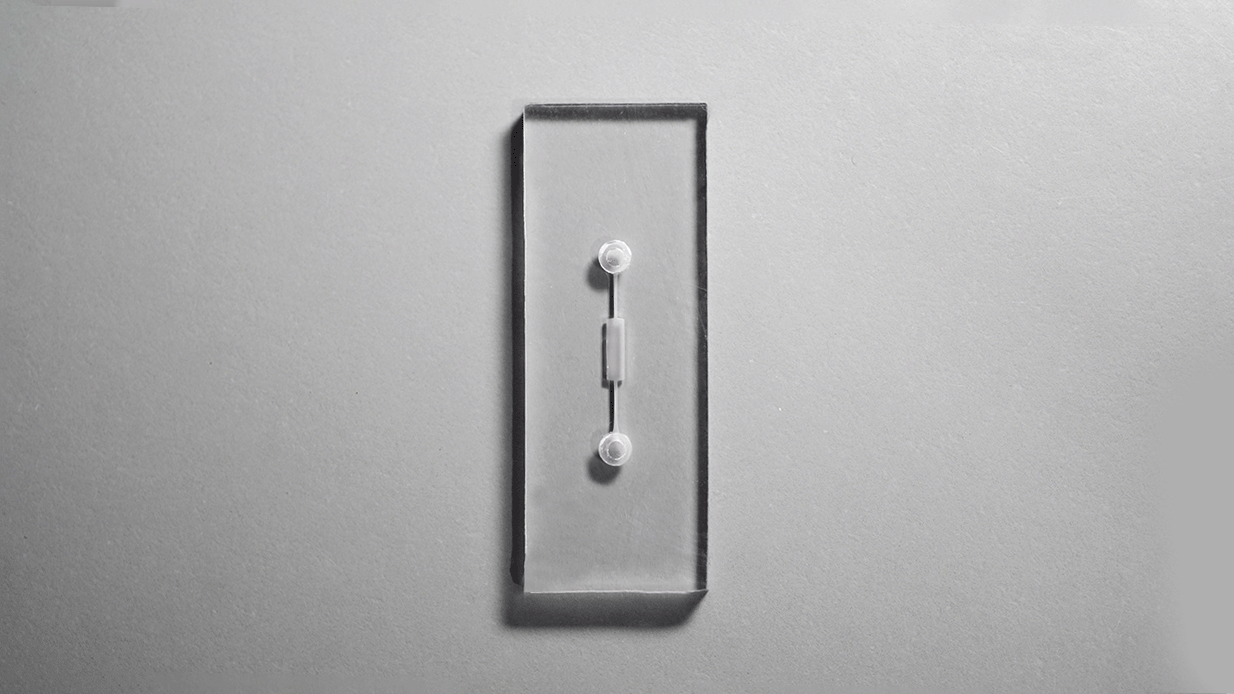

Microfluidic Cell Culture Chamber

Spiral Microfluidic Mixer

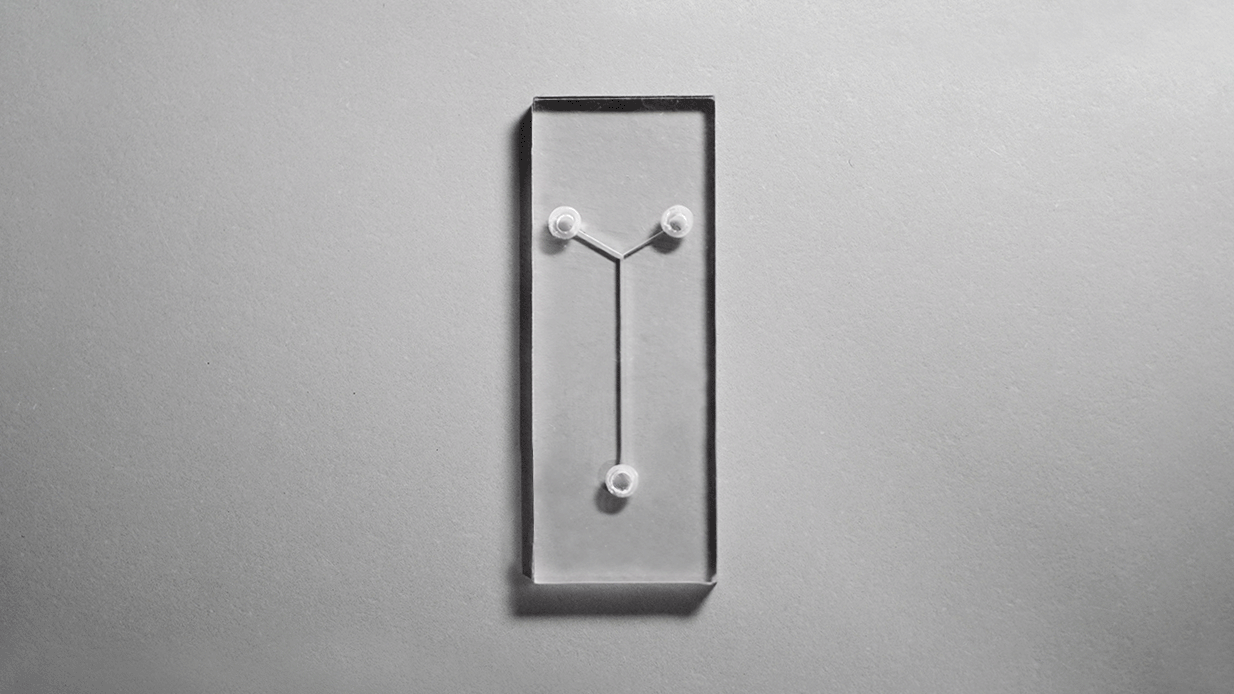

Y-Shape Mixer

250+ Universities & Institutes ‧ 10+ Fortune 500 ‧ 25+ Countries

Empower Research Worldwide

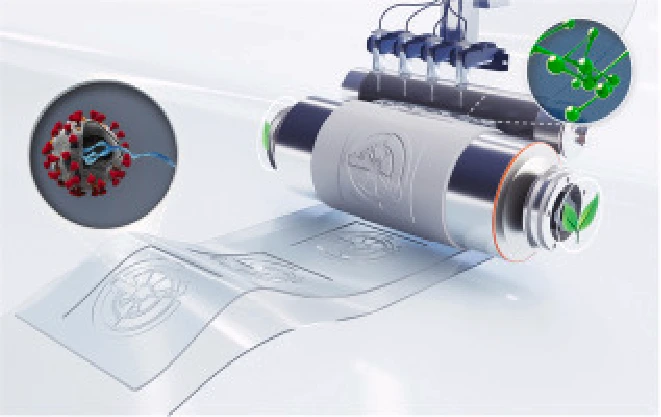

2023 | Sungkyunkwan University

Room temperature roll-to-roll additive manufacturing of polydimethylsiloxane-based centrifugal microfluidic device for on-site isolation of ribonucleic acid from whole blood

2023 | University of Hawai'i

Skin-interfaced microfluidic systems with spatially engineered 3D fluidics for sweat capture and analysis

2022 | University of Virginia

Applied tutorial for the design and fabrication of biomicrofluidic devices by resin 3D printing

2020 | University of Technology Sydney

Rapid Softlithography Using 3D-Printed Molds

Recent News

Stay current with microfluidic research, materials, and methods

Be First to Know

To subscribe to our newsletter and receive valuable updates regarding our microfluidics solution, kindly accept cookies. Without accepting cookies, the subscription option will not be available