MICROFLUIDICS MADE EASY FEATURING FLUI’DEVICE

No CAD Experience?

We Have the Solution.

Designing microfluidic devices used to be complicated. Now, with our Exclusive Partnership with FLUI’DEVICE, it’s simple. Just drag and drop your design in their user-friendly software, which requires no CAD experience. In about 15 minutes, your device is ready to print.

THE FLUI'DEVICE PLATFORM IS NOW AN OPTIONAL ADD-ON WHEN ACQUIRING OUR COMPLETE 3D PRINTING SYSTEM

Create microfluidic devices at benchside in 1 day

From Design to Reality.

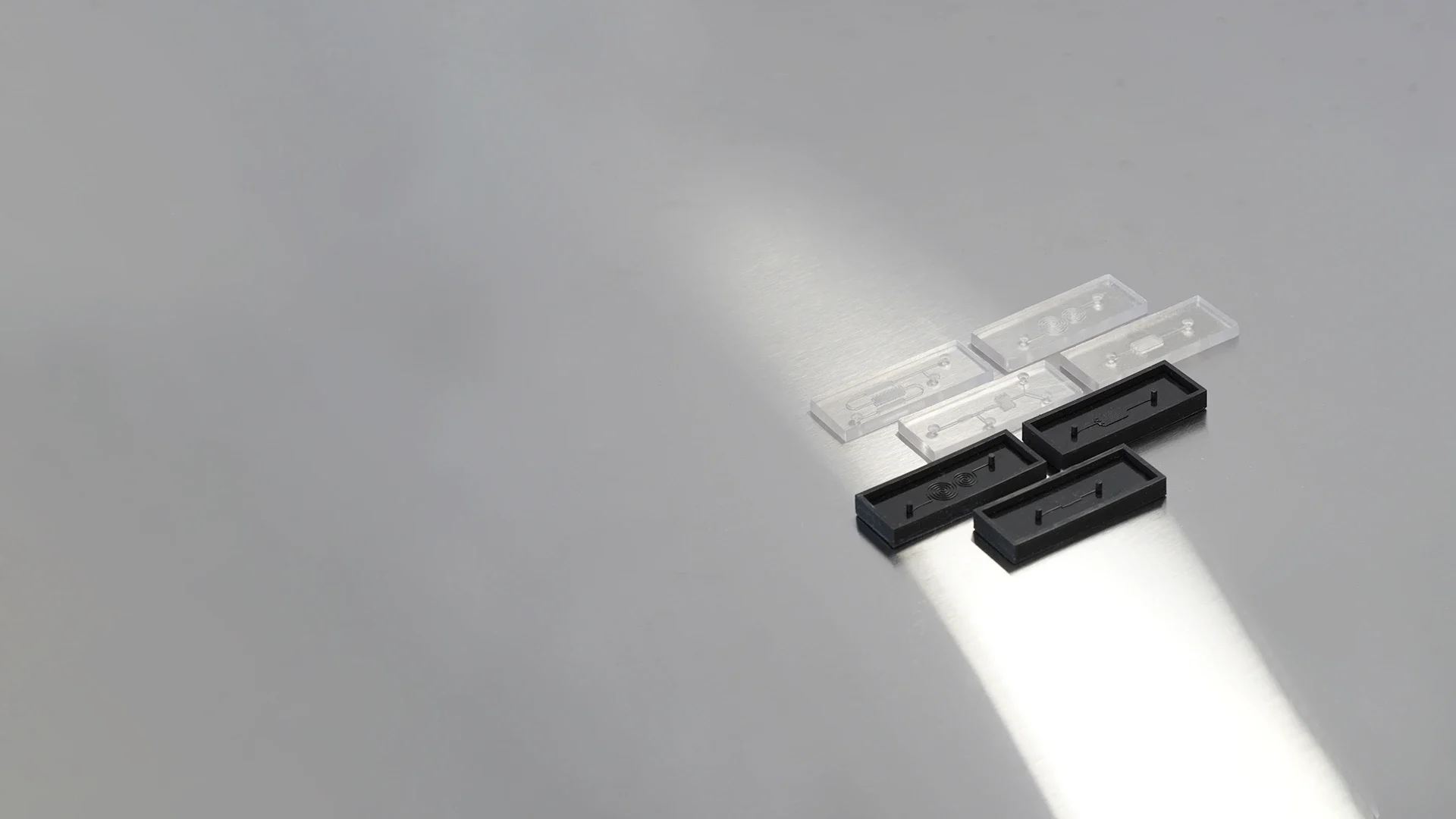

Researchers can now design, iterate, and 3D print microfluidic devices entirely in-house — no need for outsourcing or cleanroom access. With our advanced 3D printer and 3D materials made for microfluidics, you can rapidly prototype and test custom devices directly from your bench.

Our specialists are here to answer your questions.

Swipe to See How Easy It Is

No CAD Experience is Required to Design and Fabricate Microfluidic Devices.

Drag & Drop.

Design Devices in 15 Minutes.

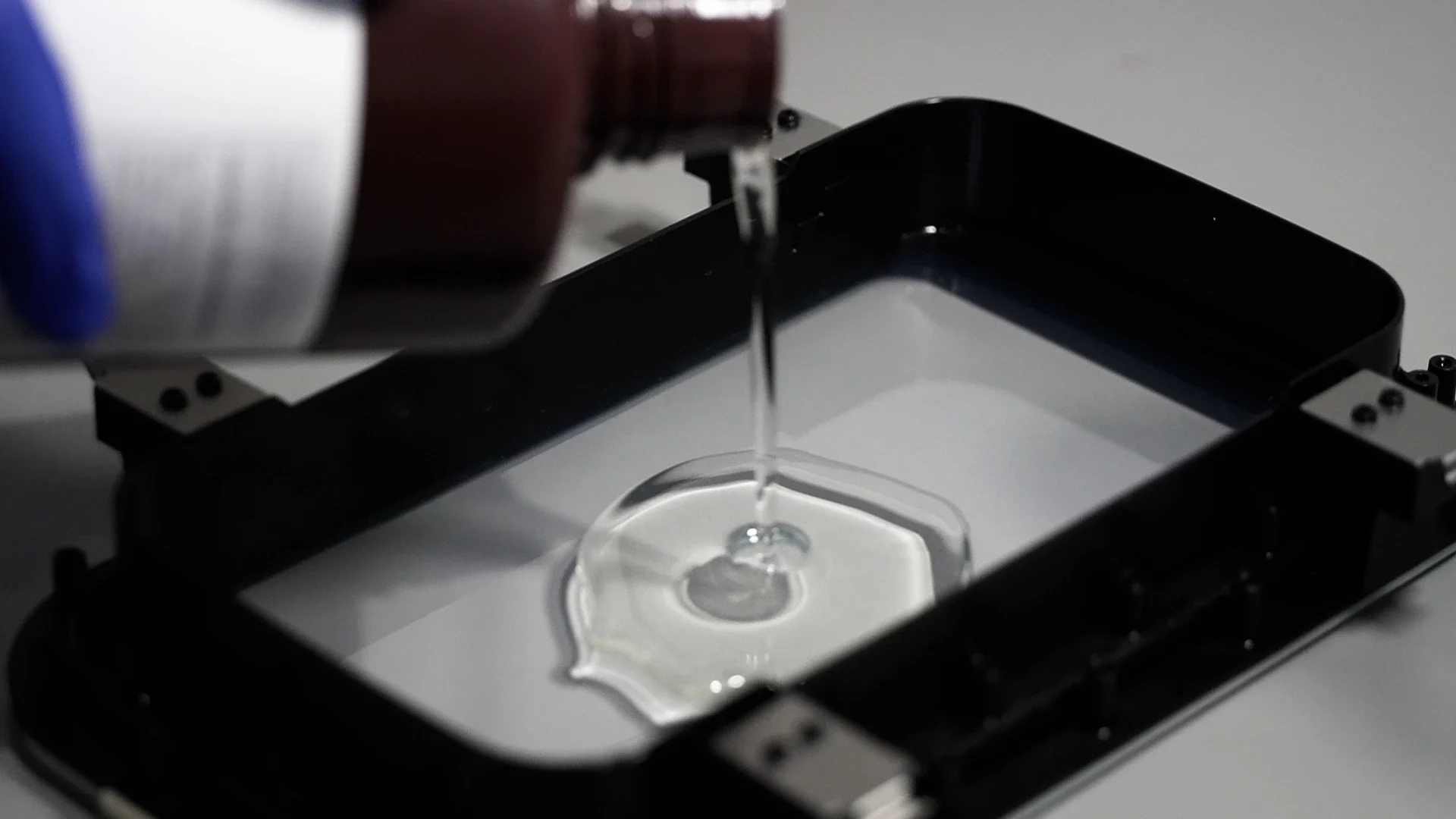

At CADworks3D, we provide a complete 3D printing system that makes it easy for researchers to create high-resolution master molds—right at the bench. There is no need for cleanroom access or complicated fabrication steps. Just 4 simple steps : CAD, Pour, Print and Clean. You can have a functional mold ready within a day.a

Our complete 3D printing system is powered by the ProFluidics 285d, an advanced 3D printer built specifically for microfluidics, lab-on-a-chip devices, and biomedical research. It offers reliable performance, sharp feature resolution, and full compatibility with standard CAD software. This all-in-one solution simplifies microfabrication, speeds up prototyping, and brings precision manufacturing into any lab setting.

Limited Access to a Cleanroom?

Applications

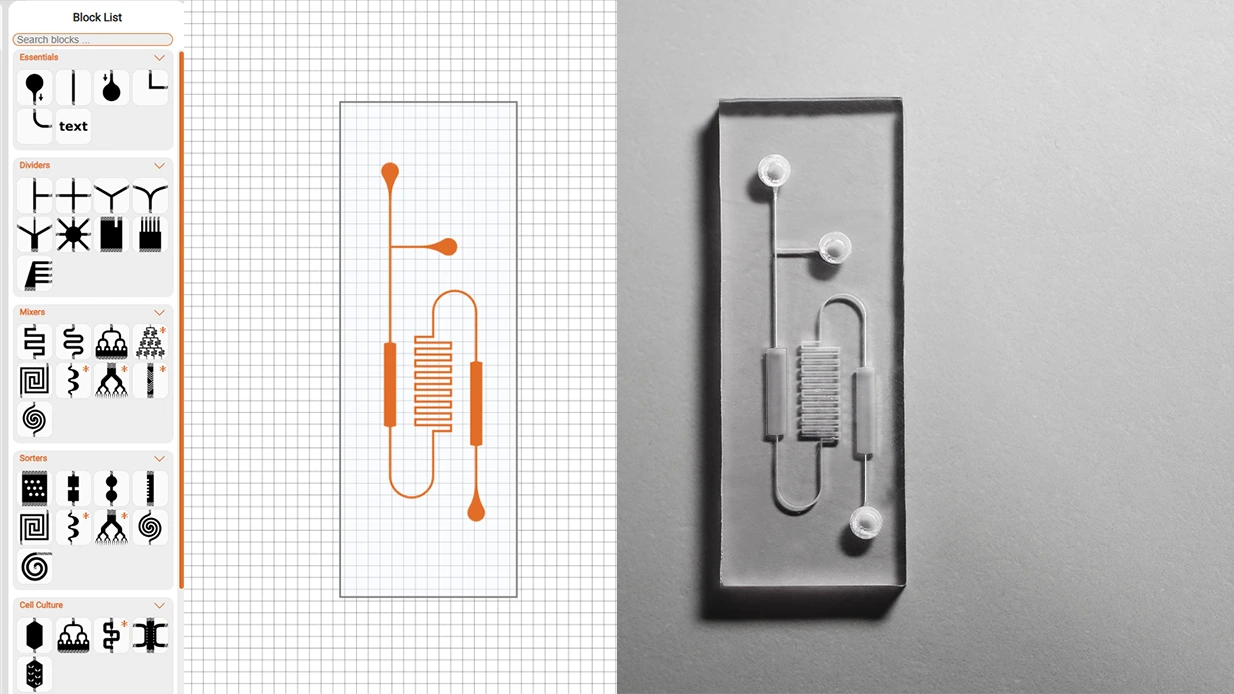

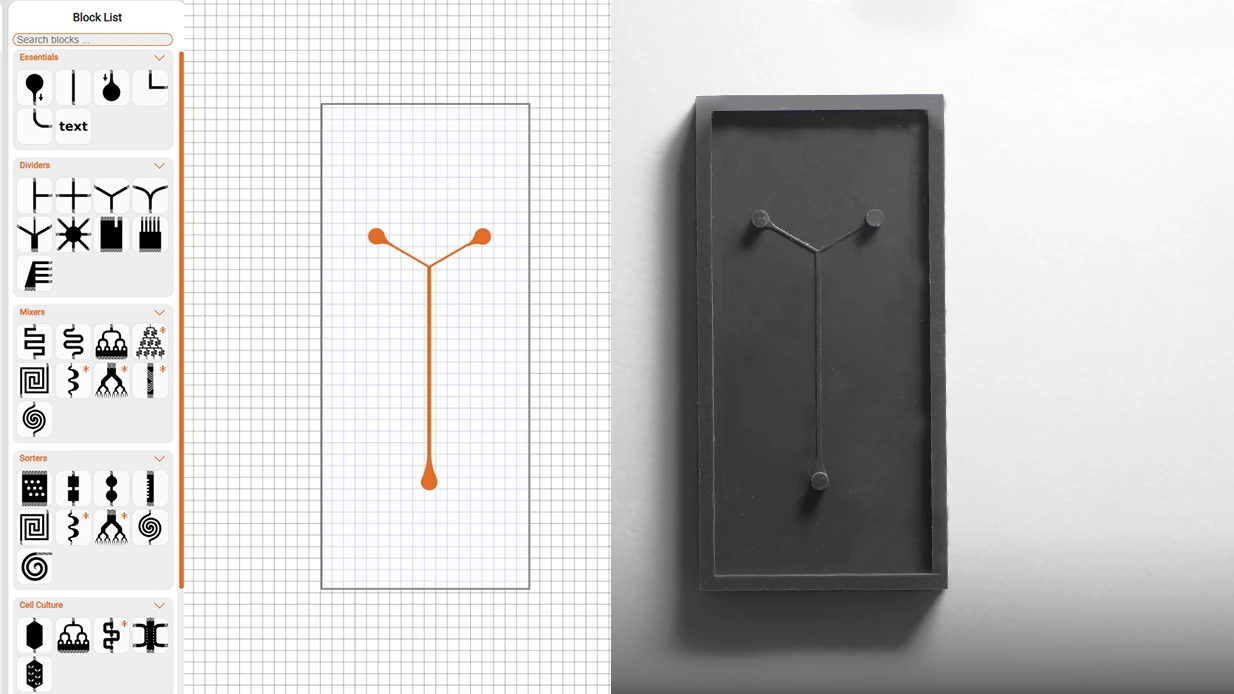

Every microfluidic device is simply a network of channels and features designed to create droplet generators, separators, mixers, gradient generators, and more. FLUI’DEVICE simplifies the design process by allowing you to quickly choose from an extensive library of ready-made channels and features. These include, but are not limited to, straight, spiral, and serpentine channels; viewing chambers; inlets and outlets. Once the design is finalized, CADworks3D provides you with a complete 3D printing system to fabricate your devices, capturing these intricate structures with precision and accuracy.

-

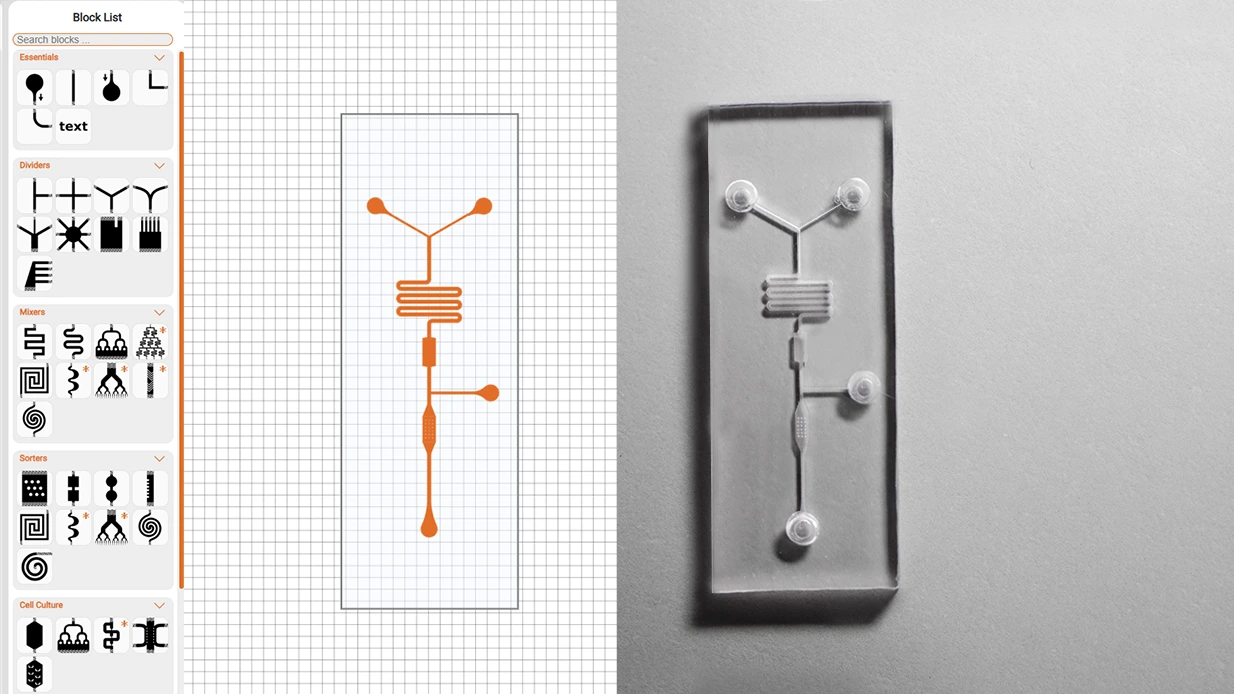

Dual Mixer

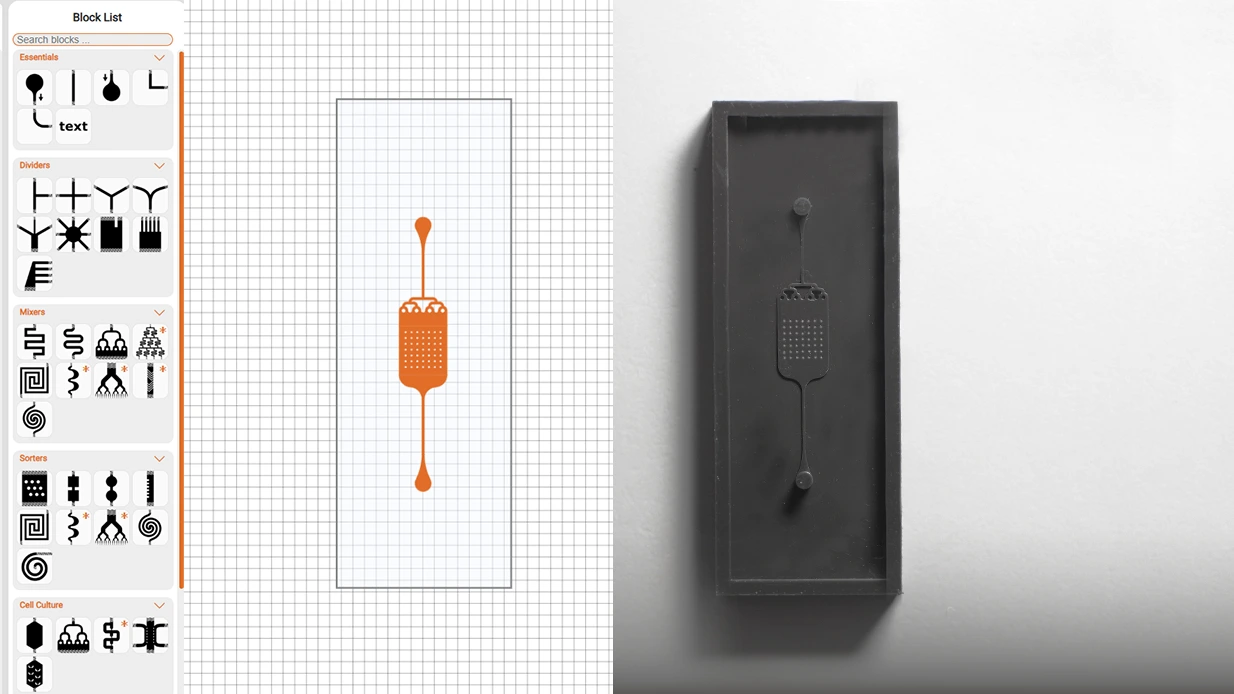

- Mixer + Filter

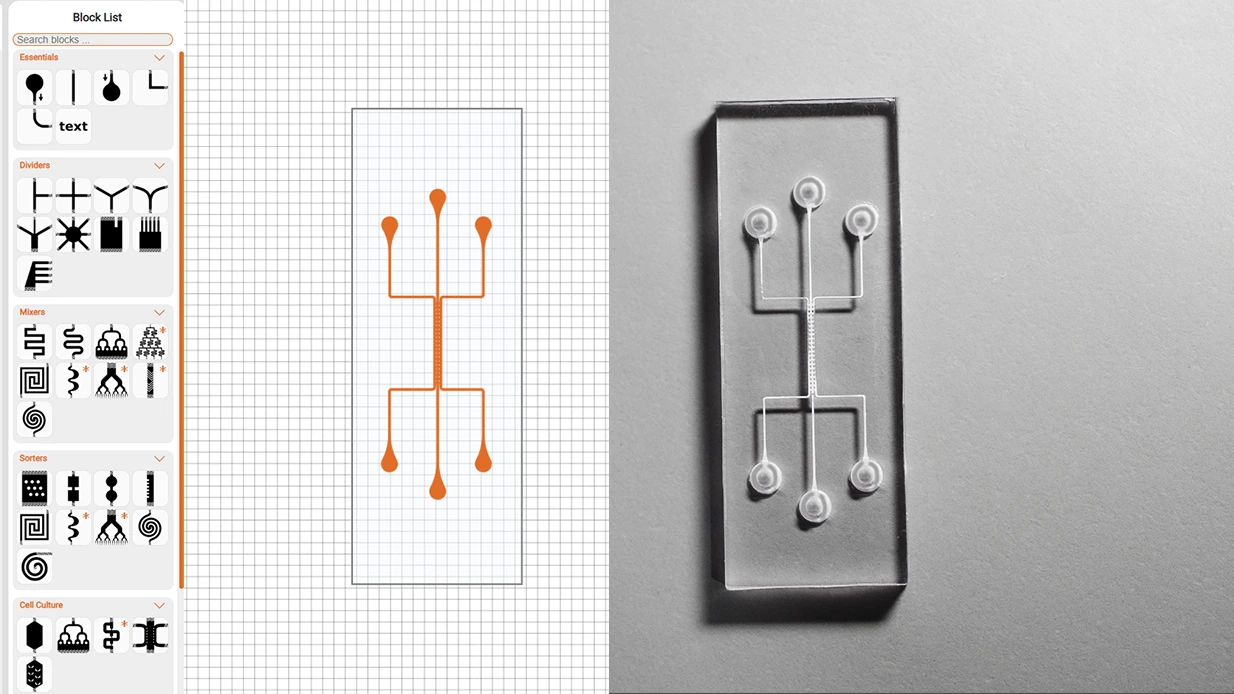

- Parallel Mixer

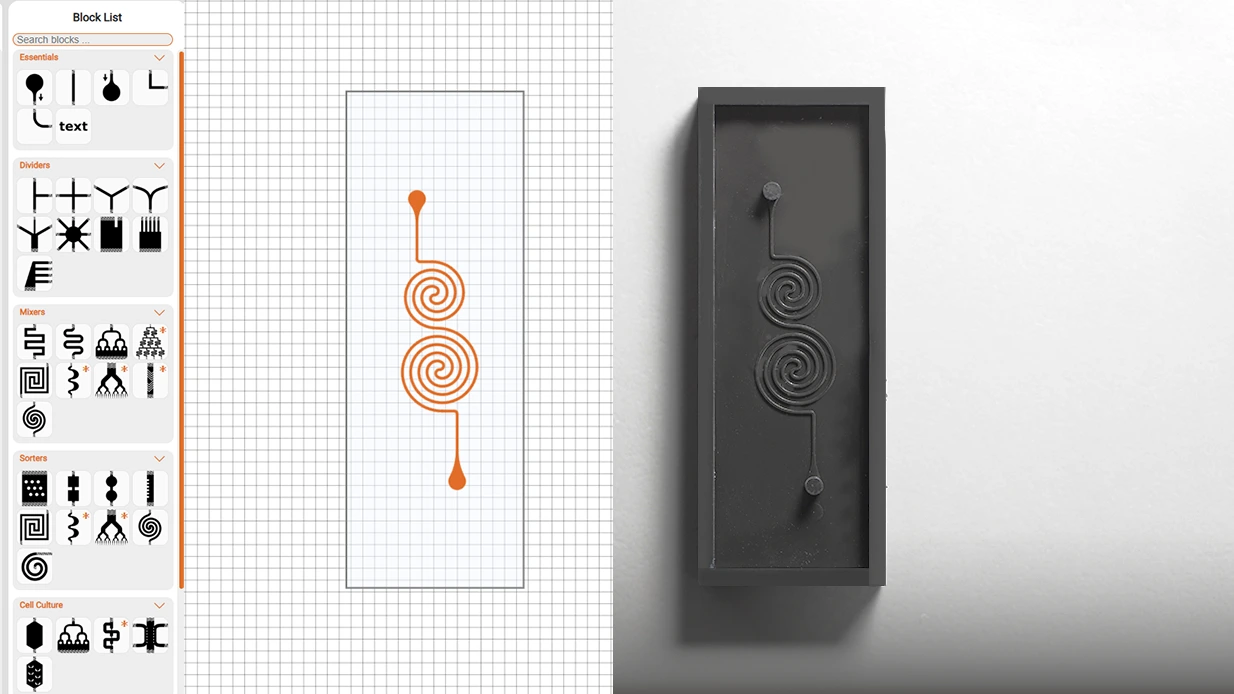

- Spiral Mixer

- Gradient Generator

- Y-Mixer

CAD File (Left) ; Microfluidic Device (Right) that was fabricated using Cyto-Clear Photopolymer Resin

CAD File (Left) ; Microfluidic Device (Right) that was fabricated using Cyto-Clear Photopolymer Resin

CAD File (Left) ; Microfluidic Device (Right) that was fabricated using Cyto-Clear Photopolymer Resin

CAD File (Left) ; Microfluidic Device (Right) that was fabricated using Master Mold for PDMS Photopolymer Resin – Rapid HD.

CAD File (Left) ; Microfluidic Device (Right) that was fabricated using Master Mold for PDMS Photopolymer Resin – Rapid HD.

CAD File (Left) ; Microfluidic Device (Right) that was fabricated using Master Mold for PDMS Photopolymer Resin – Rapid HD.

Are These Challenges Holding Back Your Research?

Take too long to fabricate molds for PDMS devices?

The Master Mold for PDMS Photopolymer Resin is a 3D material that delivers patterned master molds for casting PDMS devices. 3D print molds with a minimum feature size of 50 µm (XY), and an ultra-smooth Ra value of ~0.18 µm. Then cast a non-cytotoxic PDMS with no coatings, release agents, or cleanroom needed. Make a ready-to-test PDMS device in one day.

Can't find any cell-viable 3D materials?

The Cyto-Clear Photopolymer Resin is a 3D material that is optimized for fabricating broad-spectrum biocompatible monolithic devices. Whether you are prototyping point-of-care devices for future commercial use, or just stress-testing complex fluidic systems, you can validate several different designs and test them with live cells (over 90% cell viability) in one sitting.

Ready To Print?

In microfluidics, precision and time are everything. It’s essential to work with 3D printers that are advanced, and don’t compromise ease of use. Our 3D printing system ensures seamless integration between 3D printer, material and methodology – so researchers can efficiently fabricate devices without wasting time or resources.