Gradient Generator

3D Print Your Microfluidic Devices in a Day.

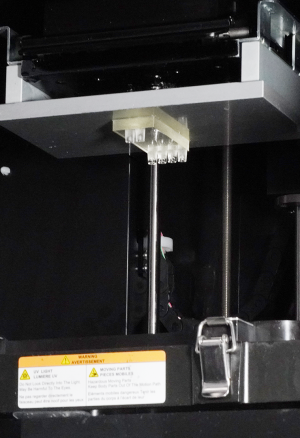

3D Print at Your Lab Bench with ProFluidics 285D

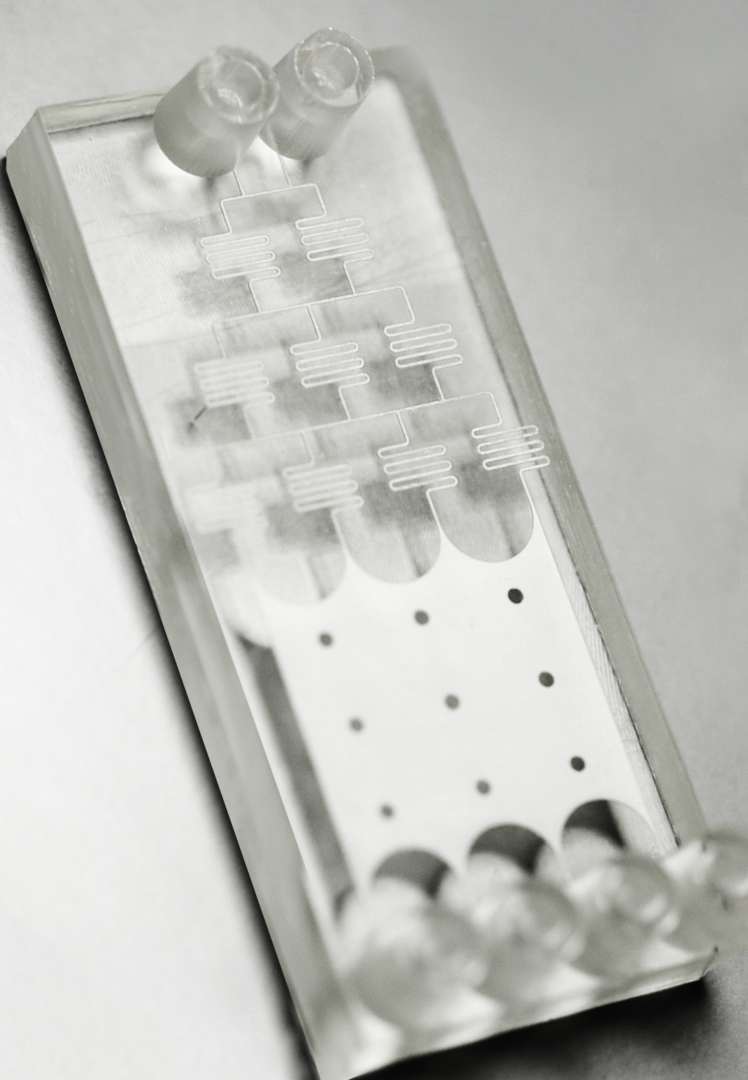

Gradient generators are essential tools in microfluidics research, enabling precise control over concentration profiles across microscale environments. They have broad utility in fields such as:

Drug screening and development

Cancer research

Stem cell biology

Neuroscience (e.g., axon guidance)

Environmental toxin testing

Enzyme kinetics

Traditionally, fabricating gradient generators is both time-consuming and expensive, often requiring cleanroom facilities, photolithography, and multiple iterations of design and prototyping. These constraints limit accessibility and slow down research progress.

To overcome these limitations, we developed a Complete 3D Printing System for creating a fully functional gradient generator within 1 day using readily available tools and materials in our office environment.

Apparatus & Materials Used:

A high-precision microfluidic prototyping system is used to design and fabricate the microchannels with reliable flow characteristics.

Chosen for its transparency and structural stability, allowing for easy visualization and efficient bonding in microfluidic assemblies.

4 Simple Steps to 3D Print Gradient Generator

With CADworks3D 3D printer and materials, you can create gradient generator devices right at bench side in just 4 easy steps. There’s no need to outsource your intellectual property as you can prototype devices in-house with multiple iterations quickly and efficiently.

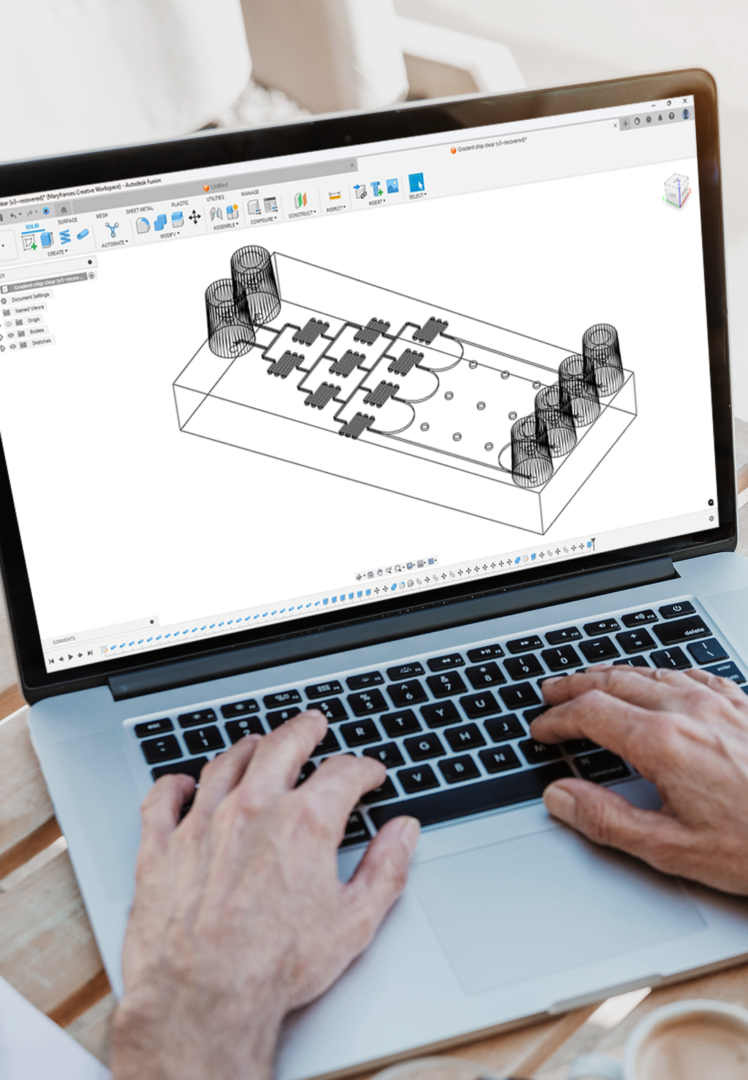

01 - CAD

Create the device’s layout, including channels, chambers, and features using CAD software.

No CAD Experience? We have a solution.

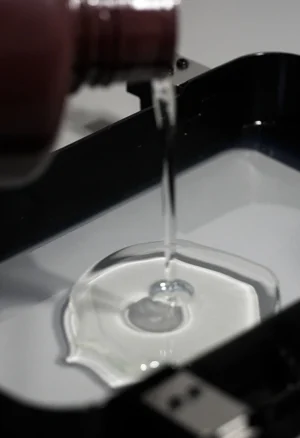

02 - Pour

Pour the specialized Rapid HD 3D material in the VAT, and put it in the printer.

03 - Print

Print the design using our CADworks3D printer with materials suited for microfluidics.

04 - Clean

Post-processing involves cleaning the device with IPA and curing it under UV light.

Learn How Our Technology Can Work for You.

Schedule a meeting with us to discuss how we can support and empower your research.