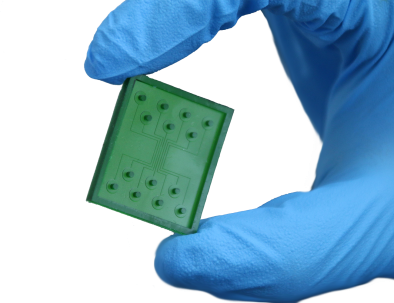

Create Master Molds for PDMS

Create reusable master moulds within one hour (dependent on height) utilizing the CADWorks3D µMicrofluidics Printer and our proprietary resin developed for PDMS applications. Expect material costs to be approximately $5 per mould (size dependent).

Case Studies

S.R.Bazaz, N.Kashaninejad, S.Azadi, K.Patel, M.Asadnia, M.E.Warkiani

Abstract

Polydimethylsiloxane (PDMS) is a long‐standing material of significant interest in microfluidics due to its unique features. As such, rapid prototyping of PDMS‐based microchannels is of great interest. The most prevalent and conventional method for fabrication of PDMS‐based microchips relies on softlithography, the main drawback of which is the preparation of a master mold, which is costly and time‐consuming. To prevent the attachment of PDMS to the master mold, silanization is necessary, which can be detrimental for cellular studies. Read More

H.Sorotsky, M.Aparanthi, D.Z.Wang, F.McFadden, S.N.Popescu, R.M.Mohamadi, M.Pereira, J.Weiss, D.Patel, S.Majeed, M.Cabanero, A.G.Sacher, P.A.Bradbury, N.B.Leighl, F.A.Shepherd, M.S.Tsao, G.Lui, S.O.Kelly, B.H.Lok

Abstract

Background: Tumor heterogeneity and evolution of SCLC is poorly defined. Serial longitudinal interrogation of tumor heterogeneity from CTCs detected in peripheral blood patient (pt) samples is a potential strategy to address this gap in knowledge. Read More