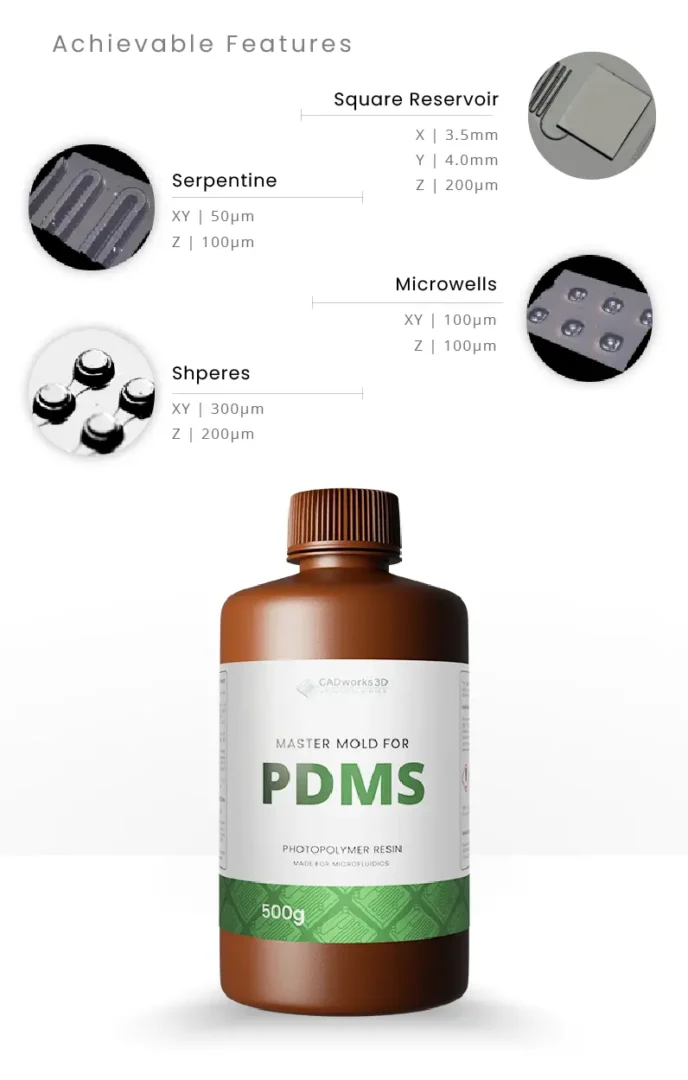

THE CAPABILITIES ARE UNIQUELY ENABLED BY THE PROFLUIDICS 285D AND ARE FULLY COMPATIBLE ONLY WITH THIS SYSTEM.

4 Simple Steps to Create Master Molds At Benchside

STEP 01 | CAD

Create your master mold using CAD software

STEP 02 | 3D PRINT

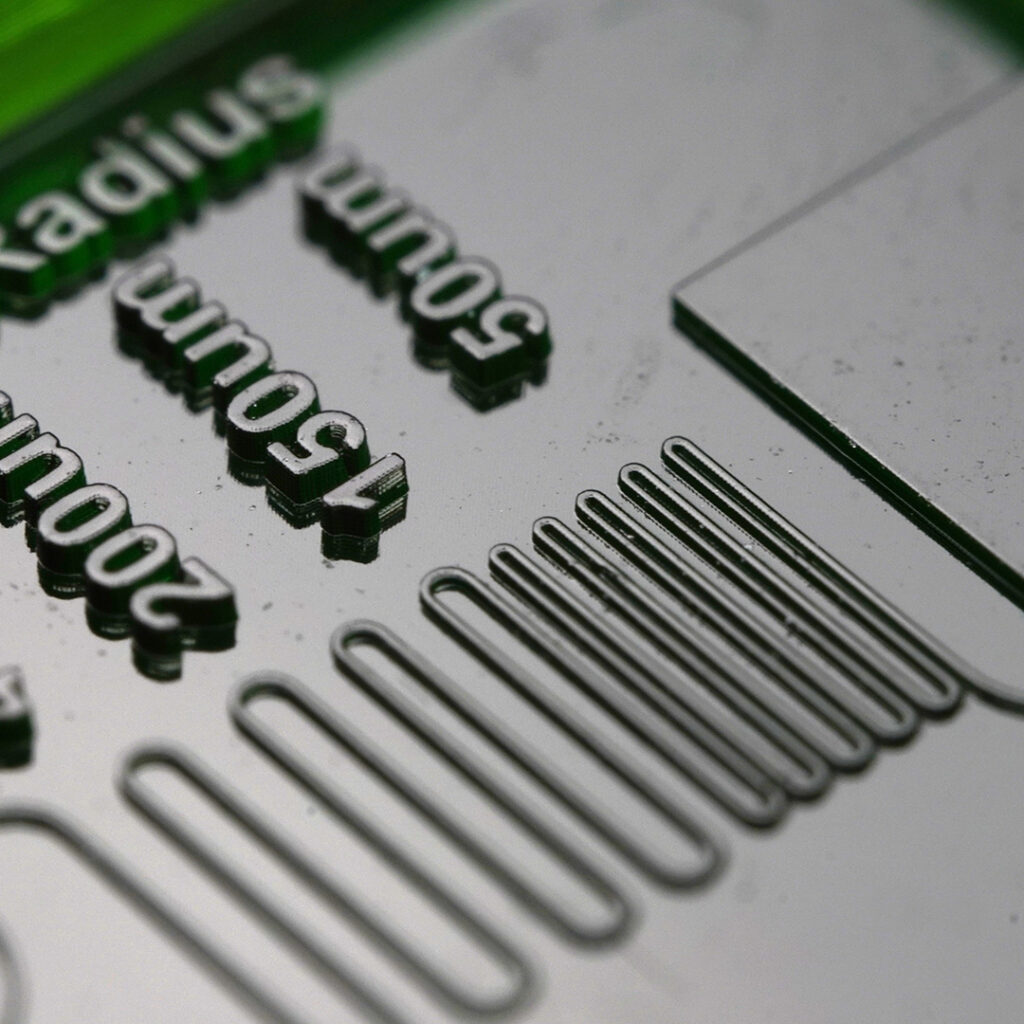

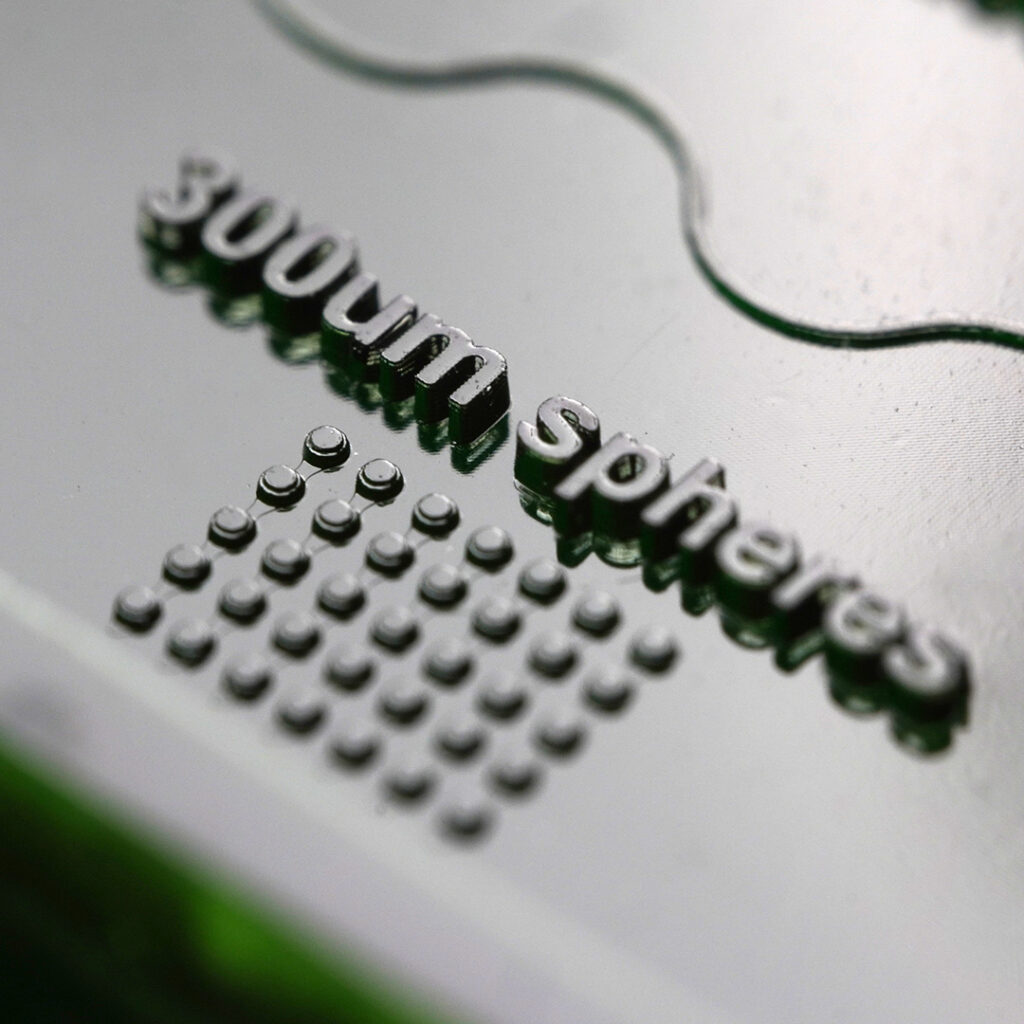

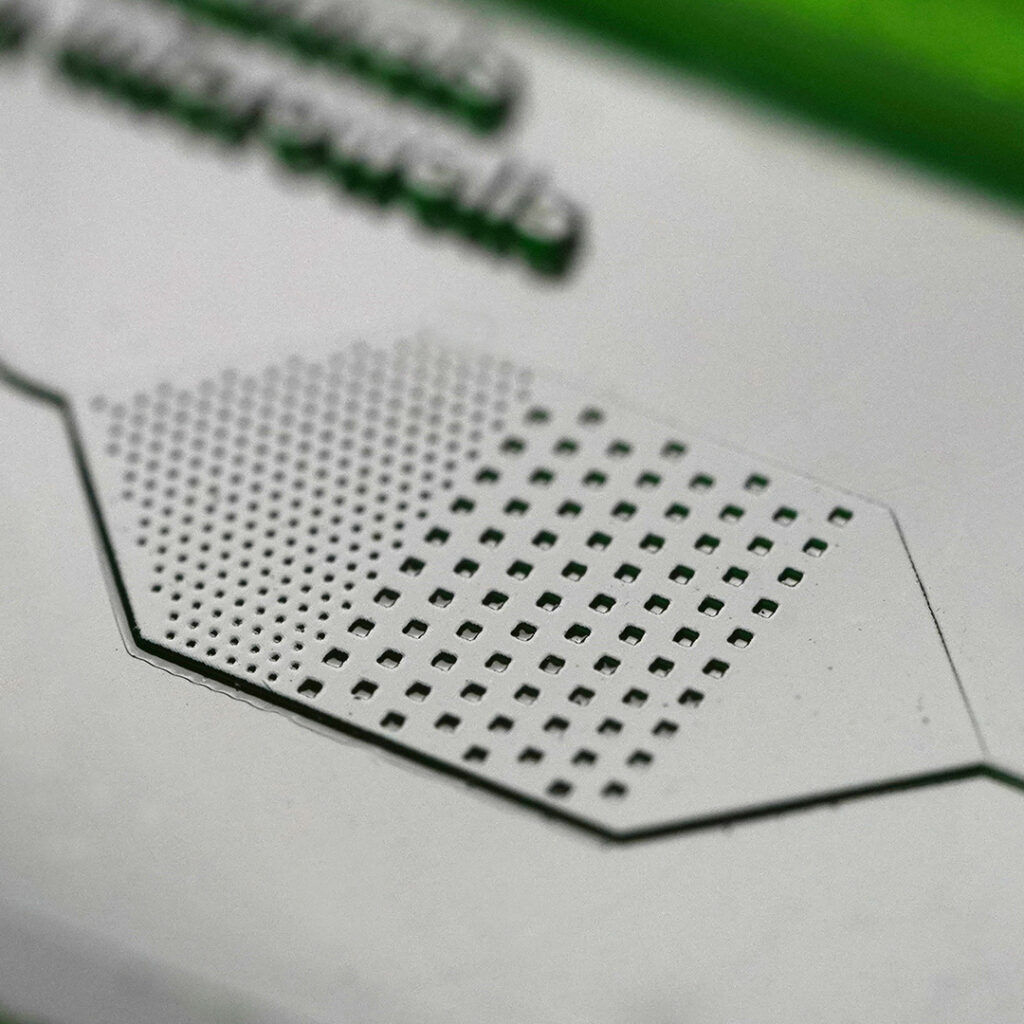

Print the master molds using our Exclusive 3D materials and 3D printer

STEP 03 | CLEAN

Quick cleaning and curing the master molds

STEP 04 | READY TO USE

Pour, cure, and peel off the PDMS from the master molds to start your research

Swipe to Explore

Case Study

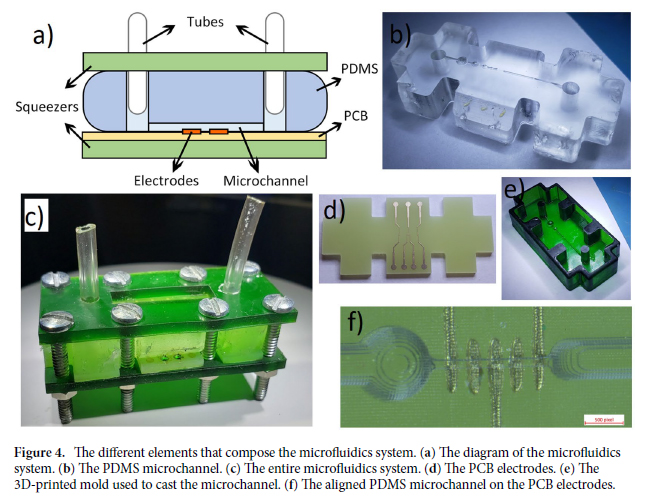

A portable device that helps detect and study microorganisms directly in the field, 3D printed with Master Mold for PDMS Photopolymer Resin

Detecting microplastics and microorganisms in the field just got easier. This study introduces a low-cost, palm-sized microfluidic device that uses impedance flow cytometry to analyze particles as small as 45 µm—no lab required. Built with 3D printing and PCB tech, it offers a new approach to portable biosensing with high precision and minimal power.

Interested In this 3D Material?

Discover the best solutions for your research.

OR

Our specialists will answer all your questions.

FREE SAMPLE PACK

Find out if our solution meets your needs by examining the printing results first hand

RESEARCH ARTICLES

Peruse a collection of peer-reviewed articles from users of our 3D printing solution

RESEARCH HIGHLIGHTS

Read condensed summaries highlighting how users utilize our 3D printer and materials

REQUEST A QUOTE

By filling out this quote request form, you are opting in to receive email updates from us. These updates may include promotional offers, industry insights, and product information. You can unsubscribe from these emails at any time by following the instructions in the footer of our emails.